Material Specification It

Reliable saddle clamp solutions for branch connections in fire protection, HVAC, and industrial piping applications.

A pipe saddle clamp is a mechanical fitting designed to create branch connections directly on existing pipelines without cutting or welding. It is widely used in grooved pipe systems where fast installation, flexibility, and system integrity are required.

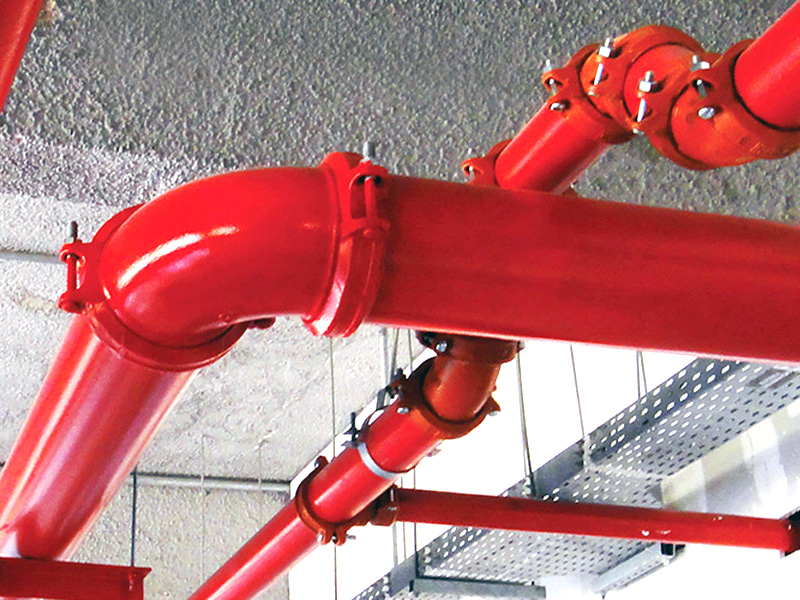

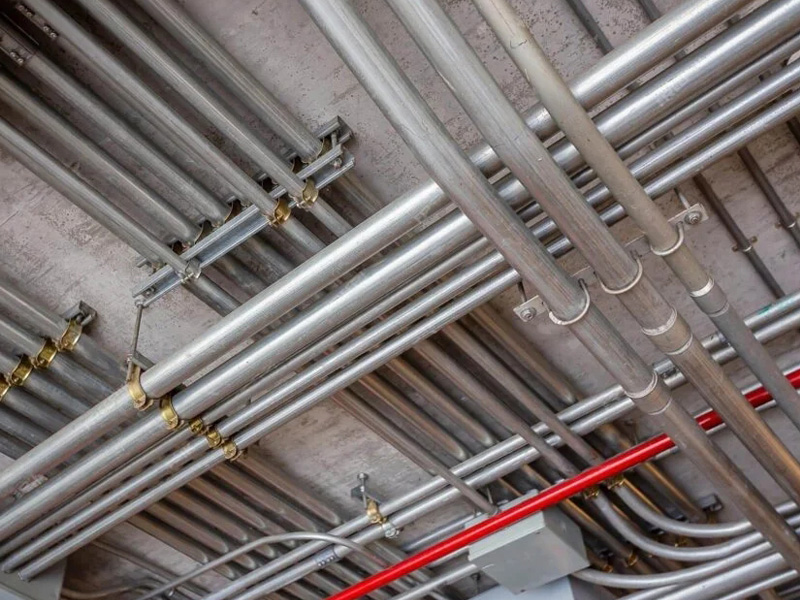

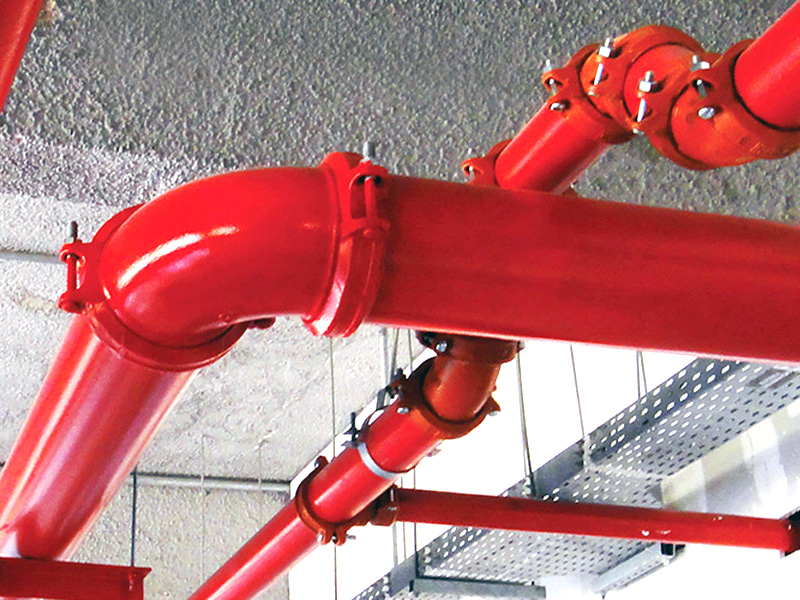

Pipe saddle clamps are commonly applied in fire protection systems, HVAC piping, and industrial fluid transport networks, allowing new outlets to be added efficiently while maintaining pressure performance.

Pipe saddle clamps are an essential branch fitting within grooved pipe fittings systems, commonly used in fire protection, HVAC, and industrial piping applications.

The pipe saddle clamp is mounted directly onto the outer surface of the main pipe. A precision-machined outlet creates a sealed branch opening, while the saddle housing distributes mechanical load evenly around the pipe circumference.

By tightening the bolts, the gasket forms a secure seal, ensuring leak-free performance under system pressure. This design allows for quick installation without pipe disassembly or hot work.

Fast installation without welding or threading

Strong mechanical support for branch connections

Reliable sealing performance under pressure

Compatible with grooved pipe systems

Reduced installation time and labor costs

Easy maintenance and system modification

Pipe saddle clamps are widely used across multiple piping systems, including:

Pipe saddle clamps are manufactured using high-strength ductile iron to ensure durability and long service life. Standard surface treatments provide corrosion resistance suitable for indoor and outdoor installations.

Common options include epoxy coating and galvanized finishes, helping the clamp withstand harsh environmental conditions and meet industry standards.

As part of complete grooved pipe fittings solutions, pipe saddle clamps allow secure branch connections without cutting or welding the main pipe.

Pipe saddle clamps are available in multiple size ranges to match common grooved pipe diameters. They are designed to be compatible with standard grooved piping systems used in fire protection and industrial applications.

Custom sizing and outlet configurations can be supported based on project requirements.

Pipe saddle clamps are designed for simple and efficient installation. With minimal tools required, installers can quickly create branch connections on-site, reducing downtime and labor intensity compared to traditional methods.

Proper installation ensures long-term sealing performance and system reliability.

Engineered to provide stable and secure branch connections under system pressure.

High-quality gasket structure ensures long-term sealing performance and reliability.

No welding or threading required, reducing installation time and labor costs.

Designed to match standard grooved piping used in fire protection and HVAC systems.

Manufactured from ductile iron with corrosion-resistant surface treatments.

Allows easy addition of branch outlets without major pipeline modifications.

Common questions about pipe saddle clamp applications, installation, and performance.

If you have any questions, please feel free to contact us. We will serve you as soon as possible and give you a satisfactory solution.

+8615610631561

leon@honcre.com

Jiankang West Street,Weifang City,Shandong Province,China